Pollution control equipment

RG Thermal Solution

Pollution control equipment

We provide comprehensive means for purifying exhaust gas emissions from various sources. Our technologies lend new-found quality and security to several vital industries, and we work continuously to improve and better meet each client’s needs.

Air Pollution Control Equipment is designed in many different ways, shapes, and forms to bring about the cleaning of manufacturing and air emitting processes.

Many industries contributes to air pollution control at thermal power plants, steel plants, chemical industry, thermal power generation, cement, metallurgy, paper making, and electronics, and a wide variety of industries. The dust removal efficiency can reach 99% or even higher under suitable conditions.

Our accumulated know-how in evaluating characteristic assessments on various dust properties and flue gas conditions, together with extensive field experience, are reflected in the ESP design.

A high voltage is applied to the discharge electrode, generating a corona discharge that produces minus ions. The electrically charged dust is accumulated on the collecting electrode by an electrical field. The collected dust is removed by rapping hammer (dry ESP), scraping brush (dry ESP), or flushing water (wet ESP).

- The purification efficiency is above 99%

- Small footprint

- Low operating cost

- Customized according to working conditions

- Energy-saving and emission reduction up to standard

Electro-static precipitator

The Cyclone Separator is a air pollution control equipment used extensively in boiler application. Cyclonic separation is a method of removing particulates from an air, gas or water stream, without the use of filters, through vortex separation. Rotational effects and gravity are used to separate mixtures of solids and fluids. A high speed rotating gas flow is established within a cylindrical or conical container called a cyclone. Air flows in a spiral pattern, beginning at the top(wide end) of the cyclone and ending at the bottom (narrow) end before exiting the cyclone in a straight stream through the center of the cyclone and out the top.

Larger (denser) particles in the rotating stream have too much inertia to follow the tight curve of the stream and strike the outside wall, falling then to the bottom of the cyclone where they can be removed. In a conical system, as the rotating flow moves towards the narrow end of the cyclone the rotational radius of the stream is reduced, separating smaller and smaller particles. The cyclone geometry, together with flow rate, defines the cut point of the cyclone.

- The purification efficiency is above 99%

- Small footprint

- Low operating cost

- Customized according to working conditions

- Energy-saving and emission reduction up to standard

CYCLOMAX

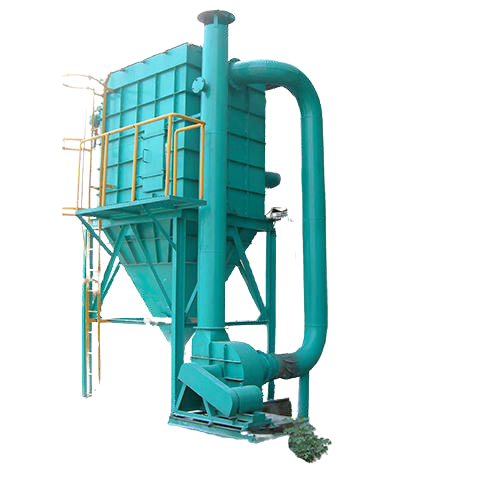

Bag Filter

we help industries control air pollution and emissions by providing long-lasting industrial filter bags. Your baghouse will collect dust efficiently when using our baghouse filter bags that meet environmental regulation standards.

Bag filters are dry separation air pollution equipment widely used to collect dust particles / particulate matter from the flue gases.

It is one of the most efficient, reliable, and cost-effective methods of gas stream filtration. It functions through interception and the prevention of particle movement.

The pulse-jet bag filter system is one of the widely used types of bag filter system.

Wet bath Scrubbers are air pollution control devices that use liquid to remove particulate matter or gases from an industrial exhaust or flue gas stream. This atomized liquid (typically water) entrains particles and pollutant gases to wash them out of the gas flow effectively.

In its most basic form, water is encapsulated in a metal or composite container. Contaminated gas is passed through the water, and the water absorbs the contaminants.

A wet bath scrubber is air pollution control equipment that removes suspended particulate matter and acid gases from waste gas streams.

The gas enters a spray tower scrubber where spm level/so (sulfur content) is reduced. Spray tower scrubbers have a minimum particle removal efficiency of 90-95%. The pollutants are removed primarily through the impaction, diffusion & absorption of pollutants onto droplets of liquid; further, the liquid containing the pollutants is collected for disposal.

- Can handle flammable and explosive dust with little risk

- Provides gas absorption and dust collection

- Provides cooling of hot gases

- Compact; can often be retrofitted into existing collection systems

- Can neutralize corrosive gases and dust particles

Wet bath scrubber