Industrial Fans

RG Thermal Solution

Industrial Fans

Boiler systems in Thermal Power plants use different types of Industrial Fans to supply air required for combustion, deliver fuel to the burners, circulate the gases for better heat transfer and remove exhaust gases. Based on the boiler size and airflow requirement, different types of fans are used with varied capabilities.

The industrial fan is designed with advanced technologies, provides increased reliability with little or no maintenance. RG thermal Solution has established itself as a quality supplier providing high quality, energy-efficient, and long life industrial fans. Our various offerings in fans range from Custom engineered centrifugal fans, Induced draft, Forced draft, Primary Air and Secondary Air Fans

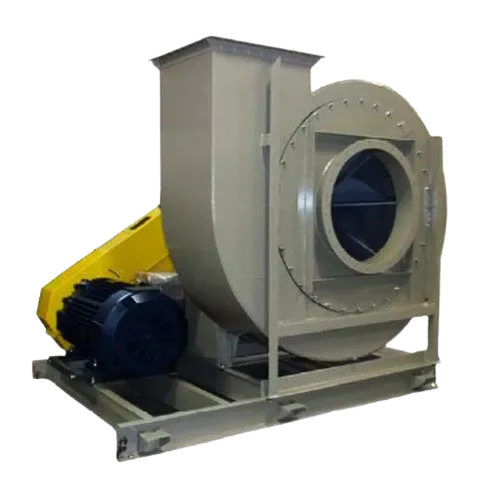

The term “Induced Draught (ID) fan” is most commonly used in the boiler industry, but more generally refers to any fans that produce negative pressure (i.e. a partial vacuum) in a combustion air system such as a kiln. Together with FD fans, they are often used to effect pressures slightly below ambient air pressure (5-10 mm of water column is one guideline that is used) and remove combustion gases from the furnace to the stack. The ID fan is started before the FD fan for this purpose.

The temperature may reach 150˚C. All leakages in the system must also be handled by the ID fan so that air leaks in, rather than ash and fuel particles leaking out. This means that the fan must be powerful enough to overcome any pressure drops in the system. It is important to minimize leaks in the flue gas path to reduce the load on the ID fan, in order to save power and ensure adequate performance. Cold air leaking into the system can cause a sharp reduction in the effective capacity of the fan, because the density of flue gases increases considerably.

ID fans may be direct-driven, belt-driven or direct coupled. The direct-driven models may only be suitable for gas temperatures that are relatively low.

ID Fans

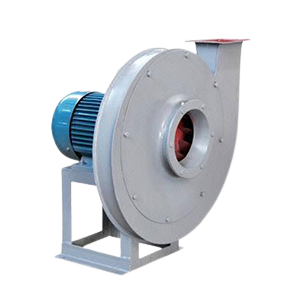

FD Fan

As we know, for a Steam Boiler to generate steam, combustion must occur, be it any fuel (wood/coal/rice husk/pet coke/LDO/Furnace oil) and for combustion to exist one of its three main requirements, is the air. And this requirement is compensated by a Forced Draft Fan.

This fan supplies air to the Air-Preheater, where it captures the heat from the flue gases coming from the Boiler Outlet.

Primary Air Fan, Secondary Air fan are the different names of Forced Draft Fan. Sometimes excess air required for complete combustion is compensated by the same FD Fan or a separate FD Fan also known as Secondary Air Fan is installed to carry out the function.

Primary air fans or PA fans are high-pressure fans, used in the boiler power plants to supply the air for transportation of coal directly from the pulverizer to the furnace. PA fans give positive pressure upstream of the coal pulverizer and handle relatively clean air.

PA fans supply air for conveying of the pulverized coal from coal mills to the furnace area. These fans produce pressure upstream of the pulverizer, to push the coal and air mixture through the pulverizer into the furnace.

PA Fans

Upto 400 degree centigrade

Upto 5,22,000 m cube/hr

Upto 300 RPM

Upto 88%